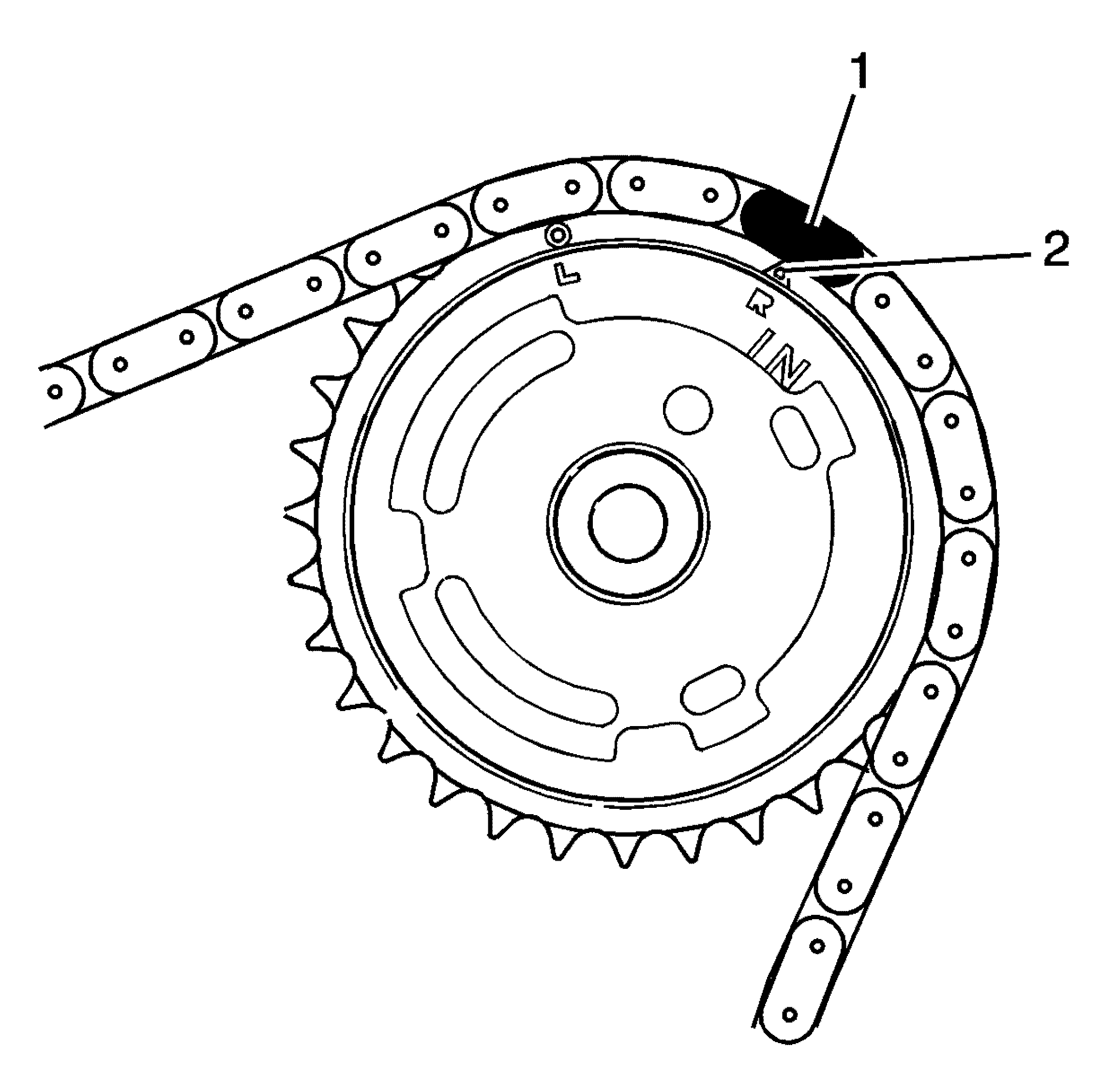

No other modifications are needed except to advance or retard cam timing as desired to dial in cam timing for the application. Installation is as simple as replacing the stock chain and sprockets with the roller chain and roller sprockets. Roller chains are available for most engine applications, including new double-roller chain kits for Chevy LS engines (previously, only single roller chains were available for the LS). Many roller chain kits come with billet steel cam and crank sprockets for added strength and wear resistance.ĭouble roller chains are used successfully in all types of performance applications, including street, drag, circle track, off-road and marine. A double roller chain is the ultimate chain setup because the two rows of rollers effectively doubles the strength of the chain - which is essential if the engine has significantly stiffer valve springs compared to stock. Link chains with larger diameter pins and stronger heat treating can add durability and strength to the cam drive.Ī roller chain is even better because the rollers reduce friction, and the larger pins and stronger links improve durability and longevity.

#Small block chevy timing belt vs timing chain upgrade

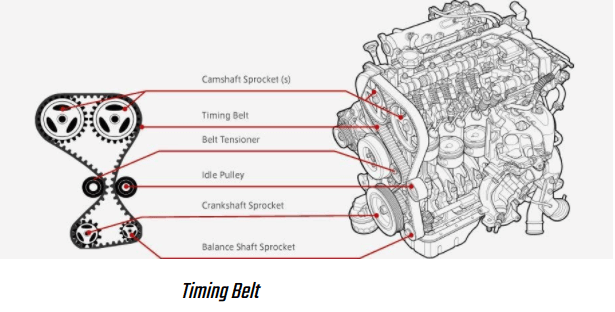

The least expensive and simplest upgrade for a stock link style timing chain is to replace it with an aftermarket performance timing set: either a beefed up link style chain or the ever popular single or double roller timing chain. Some OHC race engines have used gear drives but it takes a lot of gears to transfer drive torque all the way up to the cams. With overhead cams engines, the long distance between the crankshaft and cam(s) on top of the cylinder head(s) dictate a chain or belt drive. For inline fours and sixes, the stock setup may be a chain or a helical gear set.

For most V6 and V8 engines, the auto makers have used a simple chain drive setup because its cheap, quite and relatively durable (although chains do stretch as the miles add up). Obviously, there are a lot of ways to spin a camshaft.

0 kommentar(er)

0 kommentar(er)